Roller Cleaner 1: Technical InformationOn this page you'll find a stack of useful technical information about Roller Cleaner 1. If you have any questions about the product, feel free to contact us to find out more. Technical DataDimensions: 330mm (H) x 104mm (W) X 104mm (D)Weight: 615gm Bearing Size Range: 35mm - 95mm (NB: Outermost Bearing Diameter) Cylinder Liner: Standard-sized 450gm Grease Cartridge Liner. Comes complete with pre-oiled liner and is ready to use straight out of the box. IMPORTANT SAFETY INFORMATION:

|

|

Ensure that the black gasket is in place inside the yellow cone. |

|

Ensure that the piston and O-ring are sufficiently lubricated. |

|

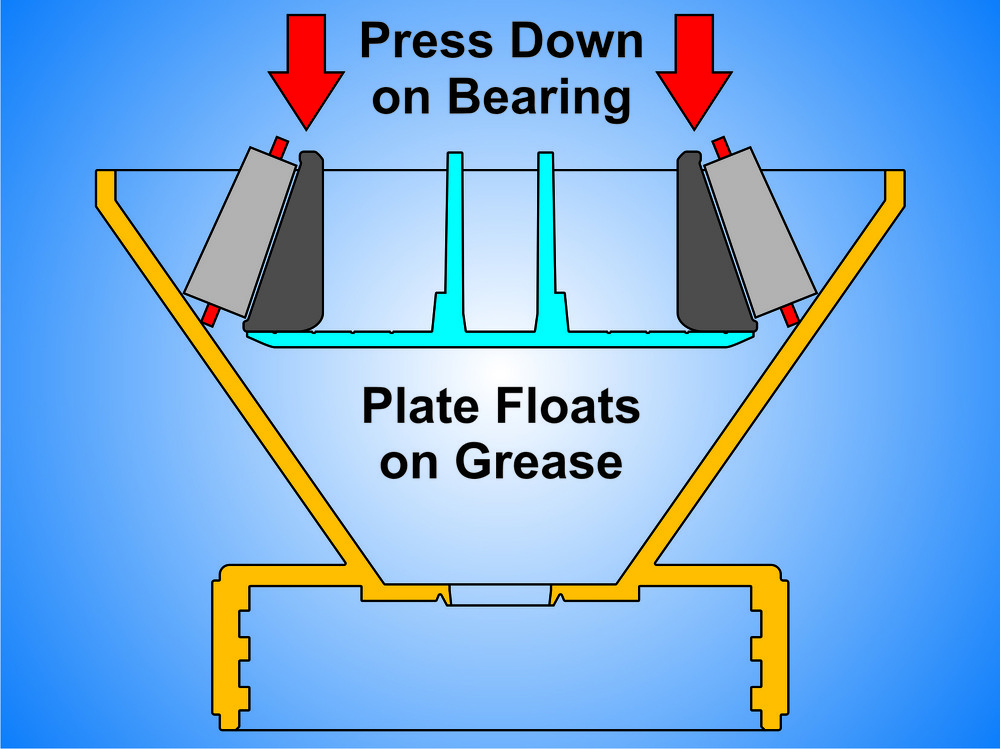

Select a suitable container and cleaning fluid. Remove the black cone plug from the Roller Cleaner. |

|

Place the black cone plug - point upwards - in the container. Place the bearing - large diameter upward - on the cone as show. |

|

Fill the container with cleaning fluid. |

|

Prepare the Roller Cleaner by fully depressing the piston shaft to the bottom of its travel. |

|

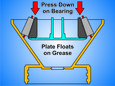

Place the yellow cone over the bearing and slowly draw cleaning fluid through the bearing by pulling the piston upwards. |

|

Repeat 4 or 5 times to flush the cleaning fluid through the rollers and bearing cage. |

|

Complete the process by fully depressing the piston shaft to the bottom of its travel to remove all of the fluid from the cleaner. |

|

Remove the bearing from the container and dry the fluid from the bearing. |

IMPORTANT: If using compressed air to dry the bearing NEVER allow the bearing to begin spinning: be sure to hold the cage to prevent cage and rollers from rotating on the race.